> Main Business > Trading & Logistic Division > Import & Export Department > CNT Composite Material

CNT Composite Material

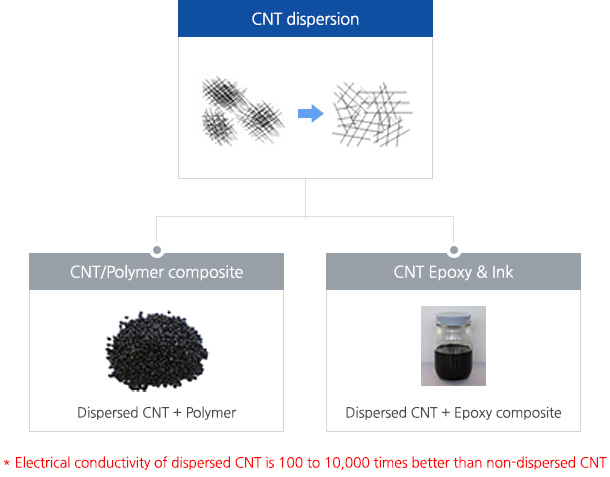

We offer technology marketing, sales and engineering service of CNT(Carbon Nano Tube) composite material for antistatic, electromagnetic absorbing and shielding, radiant heat by compound dispersed & processed CNT(Carbon Nano Tube) to all kind of plastic raw material.

CNT Value Chain

Manufacturing of CNT

- Current density : 1 × 109 A/cm² (1,000 times better than copper)

- Specific thermal conductivity : 6,000 W/m·K (10 times better than copper)

- Tensile strength : 3 × 1010 Pa (20 to 100 times better than steel)

- Elasticity : 2 to 7 times better than steel

Processing CNT composite

Patent

- CNT dispersion room and dispersion

- Cutting device

- Manufacturing of ESD, EMI material

- High efficiency thermal radiation material

- Manufacturing of contact plating polymer

- Heat dissipation, electromagnetic shielding material

- Permanent antistatic material

CNT material application field

For antistatic

- A hose for fuel spark prevention

- Door handle

- Component for semiconductor test, jig

- Semiconductor / electrical component carrying device (Tray, magazine, wheel, roller)

- Antistatic household appliances

For heat dissipation

- Tablet PC

- PCB

- Surface heat release composites

- LED housing

High strength, Lightweight materials

- Car etc. vehicle component (Tail, trim, gear, case)

- Streetlamp housing

- Robot component for medical use

- PEEK replacing ceramic etc. (High-performance sports goods)

For electromagnetic shielding / absorption

- A substrate case

- The case for TV display panels

- Telecommunication devices, RF filter

- For stealth aircrafts

– For military strategy

– Wind power generator blades

A component related to the energy

- Battery electrodes, electrolytes

- Bipolar plates for redox flow battery

Pastes, sheets etc.

- For antistatic clothes, gloves, shoes and sheets

- Paints and sheets for antistatic

- Adhesion sheet, paint for heat dissipation

- Electrical conductive paint