> Main Business > Making Food Machinery > Puffing Machine

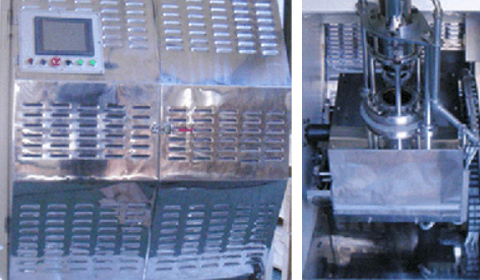

Puffing Machine

PCM550-G

PCM550-E

| Model No. | PCM550-G | PCM550-E |

| Heat Source | Gas ( LPG or LNG ) | Electric Power |

| Heat Consumption | Capacity : 35,000 kcal/hr Consumption : 35,000 kcal/hr |

Capacity : 12 kwh Consumption : 10 kwh ( 8,600 kcal/h ) |

| Electric Power Consumption | 3 kw/hr | 13 kw/hr |

| Production Capacity | 5 ~ 8 kg per puffing cycle ( 6 ~ 7 times puffing/hr ) |

5 ~ 8 kg per puffing cycle ( 6 ~ 7 times puffing/hr ) |

| Feeding Material | Corn, rice, wheat and cereal etc. | Corn, rice, wheat and cereal etc. |

| Working Temperature | Inside : 345℃, Outside : 400℃ | Inside : 345℃, Outside : 400℃ |

| Compressed Air Consumption | 0.5N㎥/hr per puffing machine one unit Required pressure min. 5 kg/㎠ | 0.5N㎥/hr per puffing machine one unit Required pressure min. 5 kg/㎠ |

| Power Supply | 220 V, 380 V x 3 phase / 50 ~ 60 Hz | 220 V, 380 V x 3 phase / 50 ~ 60 Hz |

| Dimension | 1,200W x 1,200L x 2,000H mm | 1,200W x 1,200L x 2,000H mm |

| Weight | 1,500 kg | 1,500 kg |

| Noise Level | In front of machine : 120 dB Out side factory : 85 dB for 1sec per every 8 min |

n front of machine : 120 dB Out side factory : 85 dB for 1sec per every 8 min |

| Control Type | PLC Control System with LCD display | PLC Control System with LCD display |

| Comparison Table | Most of heat radiated from puffing pressure container, accordingly, heat is radiated to ambient Easy maintenance work | Environmentally friendly products. Heat Radiation is neglegible due to insulated electric furnace system. Approx. 50% energy consumption than Gas Type. Maintenance cost is a little higher than Gas Type. |

Product

Puffed Grains

Barley

Rice

Corn

Adlay

Macaroni

Cereal